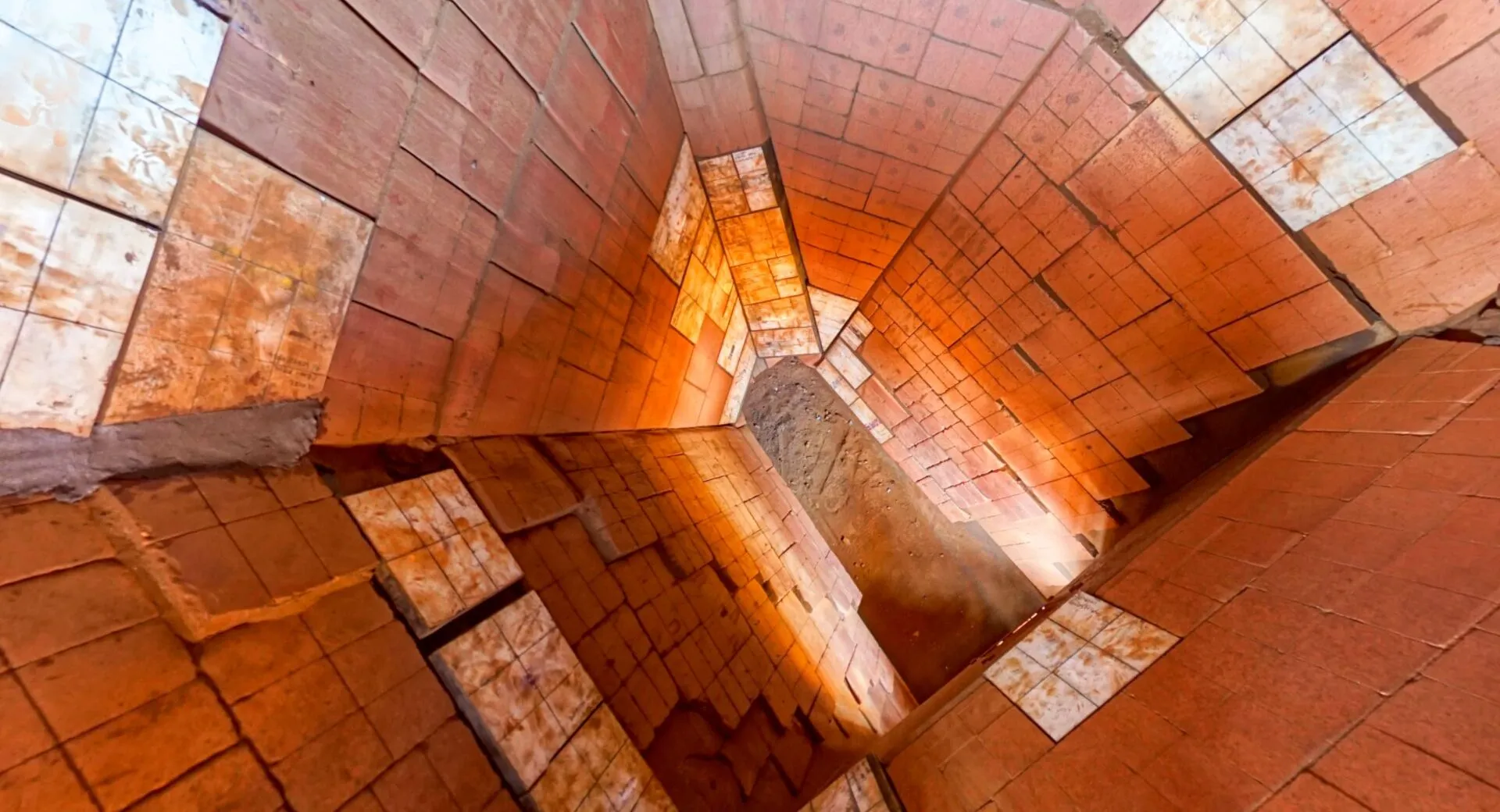

4D Delta uses a unique combination of 3D laser scanning, photogrammetry and bespoke software to safely and accurately inspect sacrificial wearing parts of ore processing plants.

Every tonne of material processed takes a bit of your plant with it. Whether transfer chutes, ore bins or grinding mills, 4D Delta can determine this loss of material thickness and calculate wear rates with our rapid data processing technology.

Our integrated service ensures maintenance optimisation, hazard elimination compared to conventional methods, and the prevention of unplanned shutdowns.

What really elevates us above the rest is our ability to deliver results and solutions almost instantly, ensuring rapid response and immediate attention to wear as it’s required.