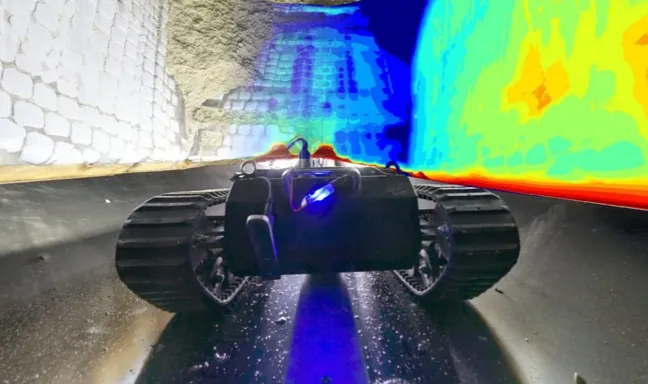

So, in conjunction with 3D laser scanning and custom-made software, we deploy cutting-edge reality capture technology to assess asset condition to the very finest detail. Combine this with the 4D Delta Cloud software suite to see these results from anywhere, and you have a world leading combination.

From spalling or moving brick, our comprehensive scanning and imaging solutions inspect every inch of the refractory vessel’s surface to accurately and remotely pinpoint any defects.

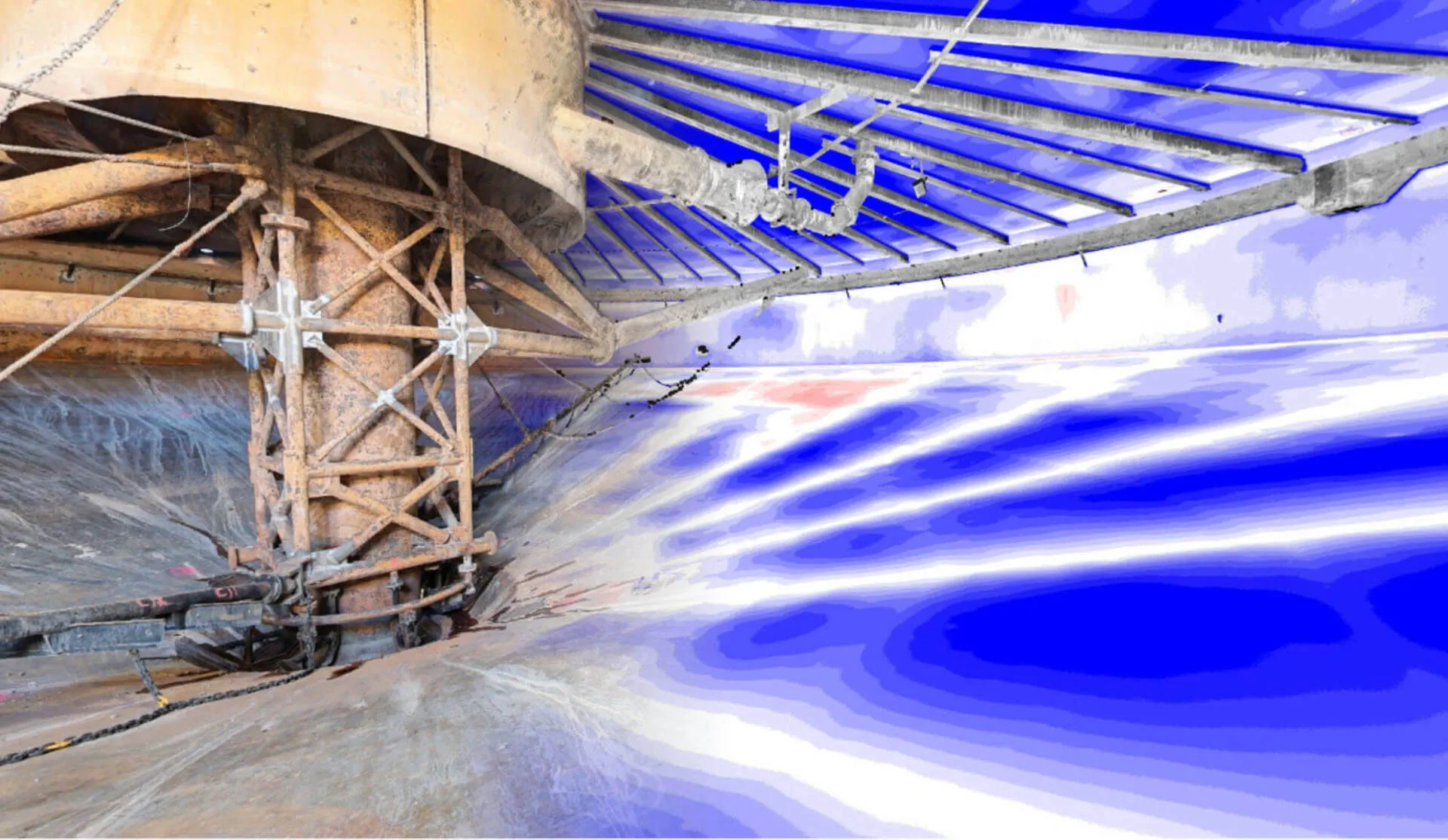

Whether it be tank shell deformation or a steel member bending or warping, our expert team can accurately pinpoint hidden deformities invisible to the naked eye, ensuring the client maintains confidence in their assets condition.

4D Delta utilises the latest 3D laser scanning technology to perform inspections on machines that require perfect alignment to operate efficiently. From Stackers and Reclaimers to Trippers and Conveyors, our technology and expertise can determine the smallest errors on the biggest machines to identify the root causes of poor performance.